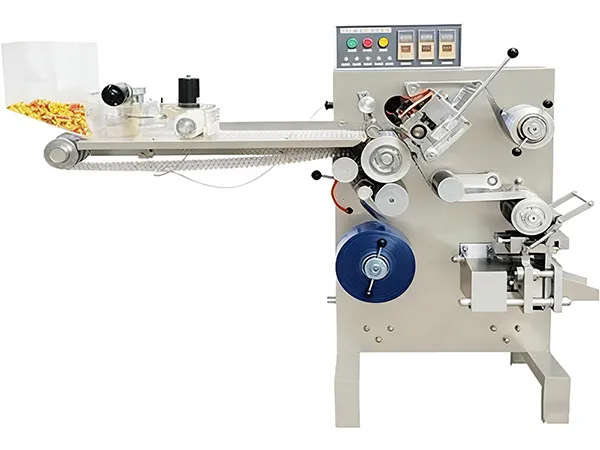

DPT130 Mechanical Drive Alu-PVC Blister Packaging Machine

Thermoforming packaging machine for Alu-PVC blister packaging of tablets, capsules, pills, and other solid dosages

The DPT130 Alu PVC blister packaging machine uses PVC and PTP as the primary packaging materials and is suitable for plain tablets, sugar coated tablets, capsules, soft gel capsules, and irregular shaped solid pharmaceutical products of various specifications.

The equipment is a platen type aluminum plastic blister packaging machine with an internal heating system. During the heating process, PVC film is heated uniformly to ensure stable blister forming. No blister loss occurs during start up or shutdown, reducing packaging material waste.

- Max. forming area: 130 × 130 mm

- Speed: 20 to 120 cuts/min or 30 to 240 blisters per minute

- Forming depth: 12 mm

- Entry level model suitable for laboratory and small scale pharmaceutical applications.

Packaging Samples

Features

- The main drive system adopts a cycloidal reducer, providing stable operation and long service life.

- Forming, feeding, heat sealing, batch coding, and punching are completed in a continuous process.

- High operational synchronization ensures clear embossing, with adjustable forming pitch for convenient mold replacement.

- A universal feeding system is configured, with a filling rate exceeding 99%.

Technical Specifications

| Punching frequency | 30-240 blisters per minute |

| Maximum forming area | 130 × 130 mm |

| PVC film | Thickness 0.2-0.4 mm, width 100-140 mm |

| PTP aluminum foil | Thickness 0.02-0.03 mm, width 100-140 mm |

| Power consumption | 3.0 kW |

| External dimensions (L×W×H) | 1700 × 900 × 1400 mm |

| Weight | 420 kg |

| Forming method | Pressure molding |

| Sealing method | Roller sealing |

| Noise level | 75 dB(A) |

| Maximum forming depth | 12 mm |

| Compressed air consumption | 1.1 m³/h (20 liters per minute) |

| Compressed air pressure | 0.5-0.7 MPa |

| Cooling water consumption | 0.19 m³/h (3.2 liters per minute) |