DPH190/220/250/260 Dual-Servo Alu-PVC Blister Packaging Machine

Thermoforming packaging machine for Alu-PVC blister packaging of tablets, capsules, pills, and other solid dosages

Alu-PVC blister packaging machine is suitable for tablet packaging and supports PVC, PTP, PDVC, PET, and Aclar films. The equipment features pressure forming, heat sealing, batch coding, and punching for automated pharmaceutical production.

Applicable Products

Technical Specifications

Dual-Servo Configuration

| Model | |

|

|

|

|---|---|---|---|---|

| Output capacity | 1.296 million units per shift (3 blisters per stroke, 10 units per blister, 90 cuts/min, 8 hours per shift) |

1.296 million units per shift (3 blisters per stroke, 10 units per blister, 90 cuts/min, 8 hours per shift) |

1.728 million units per shift (4 blisters per stroke, 10 units per blister, 90 strokes per cuts, 8 hours per shift) |

1.92 million units per shift (4 blisters per stroke, 10 units per blister, 100 cuts/min, 8 hours per shift) |

| Typical application | Entry level model suitable for R&D and small batch production with limited output requirements and budget | Standard model for small to medium batch production, meeting mainstream production needs | General purpose model with medium output capacity and strong versatility | High demand model for medium to large batch production with higher output requirements |

Production Process

-

Forming station

Forming station -

Indexing and traction station

Indexing and traction station -

Feeding station

Feeding station -

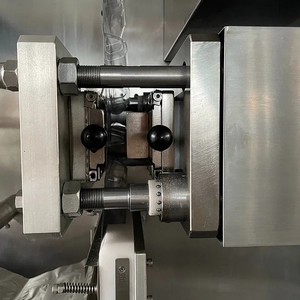

Heat sealing station

Heat sealing station -

Batch coding and perforation station

Batch coding and perforation station -

Punching station

Punching station