DPH260D/Q Triple-Servo/Full-Servo Alu-PVC & Alu-Alu Blister Packaging Machine

Universal blister machine supporting both aluminum-plastic and aluminum-aluminum packaging for tablets, capsules and softgels

- Alu-PVC: 20 to 200 cuts/min, 60 to 400 blisters per minute

- Alu-Alu: 20 to 160 cuts/min, 80 to 320 blisters per minute

- Best-selling model for medium to high volume production

The DPH260D/Q blister packaging machine is designed for medium to high volume continuous production in pharmaceutical manufacturing. The equipment is driven by servo motors. The cutting frequency is 20 to 200 cuts/min for Alu-PVC and 20 to 160 cuts/min for Alu-Alu, with a maximum output of 1.92 million units per shift (4 blisters per stroke, 10 units per blister, 100 cuts/min, 8 hours per shift).

The blister packaging machine is suitable for packaging solid dosage forms of various shapes and sizes, including tablets, capsules, soft gel capsules, and irregular shaped products. Supported materials include Alu-PVC, PVDC, Alu-Alu, and PET.

Manufactured in strict compliance with GMP and ISO 9001 quality standards, the machine features a fully enclosed stainless-steel body, ensuring packaging compliance, operational safety, and hygienic production conditions.

Packaging of capsules and tablets for pharmaceutical, food, and cosmetic industries.

- Alu-Alu blister packaging machines are formed by stamping and sealed using roller heat sealing, ensuring stable packaging efficiency and uniform blister appearance.

- A dedicated Alu-Alu feeding system enables fast loading and unloading.

- HMI and PLC control with stepless frequency regulation and servo motor drive allow one-touch parameter setting and mode switching.

- Vision inspection system uses internationally recognized brands and provides high detection accuracy.

- Multiple safety protection alarms, including material shortage, door access, temperature, air pressure, and cooling water alarms.

- Quick splicing system for packaging materials.

- Interchangeable operation between Alu-Alu and Alu-PVC formats.

- Extended filling platform improves finished product yield, with optional conveyor integration.

- Cooling options include circulating water or external tap water connection.

- Waste-free punching saves approximately 10 percent of packaging materials.

| Cutting efficiency | Alu-PVC: 20 to 200 cuts/min Alu-Alu: 20 to 160 cuts/min |

| Max. forming area | 220 × 260 mm |

| PVC film | 260 × 0.15 to 0.45 mm |

| PTP | 260 × 0.02 to 0.03 mm |

| Total power | Full-servo: 18.75 kW Three-servo: 12.75 kW |

| Power supply | 380 V, 50 Hz |

| Dimensions (L*W*H) | 4470 × 1000 × 1700 mm |

| Weight | Full-servo: 2600 kg Three-servo version: 2500 kg |

| Forming method | Alu-PVC blisters formed by pressure forming Alu-Alu blisters formed by stamping |

| Sealing method | Roller sealing |

| Noise level | 75 dB(A) |

| Automatic inspection | Vision inspection |

| Max. forming depth | Alu-PVC: 18 mm Alu-Alu: 12 mm |

| Compressed air consumption | 1.1 m³/h (20 liters per minute) |

| Compressed air pressure | 0.5 to 0.7 MPa |

| Cooling water consumption | 0.19 m³/h (3.2 liters per minute) |

Forming, indexing, heat sealing, punching, feeding, printing, robotic handling, and registration alignment are all servo-driven. All modules operate in coordinated linkage, enabling system-wide shutdown in case of faults while maintaining positional memory during power loss or stoppage. Individual modules can also operate independently for maintenance and adjustment.

Servo drive is applied to forming and indexing, active heat-sealing rollers, and punching feed. Other forming, punching, and printing stations are synchronized through mechanical transmission driven by the main motor, with speed controlled via frequency inverter. Mold changes require only parameter adjustment on the HMI, significantly reducing changeover time.

-

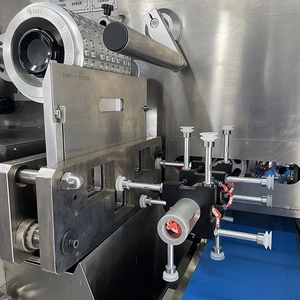

Web splicing station

Web splicing station -

Forming station

Forming station -

Rotary feeding station

Rotary feeding station -

Universal feeding station / Alu-Alu (irregular shaped) feeding station

Universal feeding station / Alu-Alu (irregular shaped) feeding station -

Heat sealing station

Heat sealing station -

Punching station

Punching station

The DPH260Q full-servo Alu-PVC blister packaging machine was introduced into a solid dosage production line to replace existing low-speed equipment that could not support upstream and downstream line integration. The equipment supports multiple product specifications with fast mold changeover. A belt drive replaces traditional chains, reducing wear, noise, and lubrication requirements, significantly improving operational accuracy and meeting multi-specification packaging demands.