The automatic cartoning machines feature a horizontal design with continuous-motion transmission, ensuring stable and high-speed operation. They are suitable for automatic cartoning of pharmaceutical blister packs, bottles, food, cosmetics, daily chemicals, and small hardware items. This equipment represents an innovative integration of optical, mechanical, electrical, and pneumatic automatic control technologies.

The equipment can continuously perform multiple leaflet folds, print production dates and batch numbers, and automatically reject cartons when leaflets are missing. The cartoning machines can operate independently or in line with other equipment. Featuring a modular structure and multi-axis servo transmission, the equipment is controlled using the computer touchscreen control system. The design ensures low noise, smooth and reliable transmission, and a low failure rate. Packaging specifications can be easily adjusted or changed according to user requirements, allowing flexible adaptation to various carton sizes.

-

Intermittent Motion Vertical Cartoner (150 cartons/min)

Intermittent Motion Vertical Cartoner (150 cartons/min)The equipment is a vertical intermittent motion cartoner. It can sequentially complete processes such as product feeding, material transfer, leaflet folding, leaflet insertion, carton erection, product insertion, and carton sealing.

-

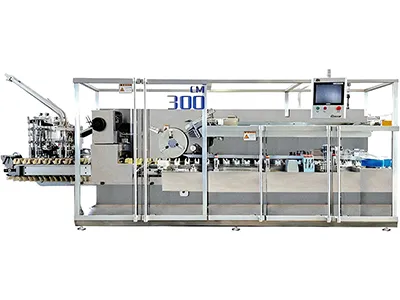

Continuous Motion Horizontal Cartoner (300 cartons/min)

Continuous Motion Horizontal Cartoner (300 cartons/min)The continuous motion horizontal cartoner features a horizontal design with continuous motion drive, ensuring stable operation and a cartoning speed of up to 300 cartons/min.

-

Continuous Motion Horizontal Cartoner (400 cartons/min)

Continuous Motion Horizontal Cartoner (400 cartons/min)The sachet packaging machines are suitable for the automatic filling and packaging of granules, tablets, and viscous materials in the pharmaceutical, food, and daily chemical industries, supporting accurate dosing for small and medium-size sachets.