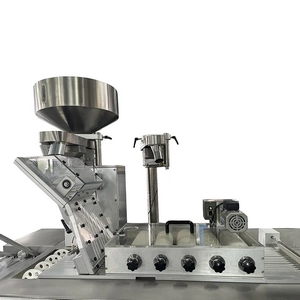

DPH250D Triple-Servo Alu-PVC & Alu-Alu Blister Packaging Machine

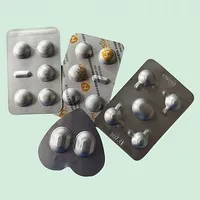

Universal blister machine supporting both aluminum-plastic and aluminum-aluminum packaging for tablets, capsules and softgels

The Alu-PVC & Alu-Alu blister packaging machine is a medium-capacity model driven by servo motors. The punching frequency reaches 20–200 cuts/min for Alu-PVC and 20–160 cuts/mins for Alu-Alu, with an output of 1.728 million units per shift (4 blisters per stroke, 10 units per blister, 90 cuts/mins, 8-hour shift).

It is suitable for packaging solid dosage forms of various shapes and specifications, including tablets, capsules, soft capsules, and irregular-shaped tablets. The equipment supports multiple packaging materials such as Alu-PVC, PVDC, Alu-Alu, and PET.

As a fully automatic packaging blister machine, it ensures full blister forming and reliable sealing, fully complying with GMP requirements.

- Equipped with an intelligent servo system and optimized transmission structure, ensuring high speed, stable operation, and reduced downtime. Suitable for medium-batch continuous production.

- Supports interchangeable Alu-Alu and Alu-PVC formats, meeting blister packaging needs across pharmaceutical, food, and chemical industries with strong adaptability.

- Utilizes energy-saving motors and precise energy control, reducing power consumption during high-efficiency operation. Waste-free punching saves approximately 10% of packaging materials, effectively lowering long-term production costs.

- HMI and PLC control, stepless frequency regulation, and servo drive enable one-touch parameter setting and mode switching. Supports multi-language interfaces, allowing operators to start quickly after minimal training.

| Cutting efficiency | Alu-PVC: 20–200 cuts/min Alu-Alu: 20–160 cuts/min |

| Max. forming area | 250 × 200 mm |

| PVC film | 250 × (0.15–0.45) mm |

| PTP | 250 × (0.02–0.03) mm |

| Total power | 12.75 kW |

| Power supply | 380 V / 50 Hz |

| Dimensions (L*W*H) | 4470 × 1000 × 1700 mm |

| Weight | 2500 kg |

| Forming method | Alu-PVC: Pressure forming Alu-Alu: Stamping |

| Sealing method | Roller sealing |

| Noise Level | 75 dB(A) |

| Automatic inspection | Vision inspection |

| Max. forming depth | Alu-PVC: 18 mm Alu-Alu: 12 mm |

| Compressed air consumption | 1.1 m³/h (20 L/min) |

| Compressed air pressure | 0.5–0.7 MPa |

| Cooling water consumption | 0.19 m³/h (3.2 L/min) |

-

Web splicing station

Web splicing station -

Forming station

Forming station -

Rotary feeding station

Rotary feeding station -

Universal feeding station / Alu-Alu (irregular tablet) feeding station

Universal feeding station / Alu-Alu (irregular tablet) feeding station -

Heat sealing station

Heat sealing station -

Punching station

Punching station

At the Guangzhou Xingqun Pharmaceutical production site, the customer required equipment upgrades and capacity expansion due to poor packaging appearance and insufficient sealing performance of outdated machines. Huaxin Package customized a DPH250D three-servo model, ensuring full and uniform blister forming for every tablet and significantly reducing packaging-related product risks.