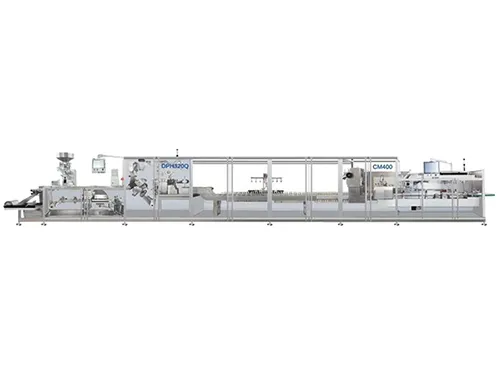

Automatic Blister Packaging & Cartoning Line

Automated packaging line integrating blister packaging machine and cartoning machine for pharmaceuticals

This automatic blister packaging & cartoning line integrates advanced technology, synchronized production, intelligent robots, and conveyor systems to automatically queue and deliver blister packs to the cartoner. The line seamlessly combines blister packaging and cartoning, featuring a rational layout, simple operation, improved production efficiency, and higher product yield. Labor intensity and production costs are reduced. The line can be connected with pillow packers, 3D packers, bundlers, shrink wrappers, and other auxiliary equipment.

The line is suitable for capsules, tablets, and shaped tablets with Alu-PVC or Alu-Alu packaging, enabling automatic blister forming, product filling, blister inspection and removal of defective units, blister queuing, carton pick-up, carton opening, tablet insertion, leaflet insertion, cartoning, and batch number printing. The fully servo-controlled line ensures GMP-compliant automated production.

- The blister packaging & cartoning line enables intelligent communication and synchronized control between the blister machine and the cartoner. Blister packs are smoothly transferred via conveyor directly into the cartoner, eliminating intermediate handling, temporary storage, and manual intervention, which maximizes line efficiency. The design ensures balanced performance and broad applicability.

- Key positions on the line monitor missing units, broken tablets, fragments, blister sealing integrity, and leaflet insertion, ensuring 100% online inspection. Servo technology provides precise, gentle mechanical movements, producing well-formed, square cartons with smooth corners, free from scratches or deformation.

- The entire line is operated via PLC and a large touchscreen, allowing parameter setting, operational monitoring, data recording, and fault diagnosis at a glance. The intuitive interface simplifies operation and reduces labor dependency.

- All parts that come into contact with the product are made of stainless steel and have smooth surfaces, with no hard-to-reach areas, making cleaning and disinfection simple and effective. Safety features include door interlocks, emergency stop buttons, and multiple protective devices to ensure operator safety.

| Production rate | For 400-pocket blisters, 1 product per pocket yields 400 units per minute, while 2 products per pocket yield 200 units per minute. For 300-pocket blisters, 1 product per pocket yields 300 units per minute, while 2 products per pocket yield 150 units per minute. |

| Power supply | 380 V, 50 Hz |

| Air pressure | 0.6 MPa |

| Dimensions (L*W*H) | 11,500 × 1,800 × 1,800 mm (extendable based on conveyors and auxiliary equipment) |

| Line length | 11,500 mm (adjustable per configuration) |

Note: For Alu-Alu (Alu-PVC) blister packaging & cartoning line, configurations can be customized according to required capacity, product dimensions, and material specifications.